[Peter] is back at it, again modding his CNC3020 router. This time he’s adding a coolant system and spindle direction control. If you have ever tried cutting plexiglass using a mill, router or even a band saw, then you know it is common for those plastic chips to melt together and form a crusty trail of goobers directly behind the cutting tool. Turning down the spindle speed helps a little but the intent of the coolant system is to eliminate the globular mess all together.

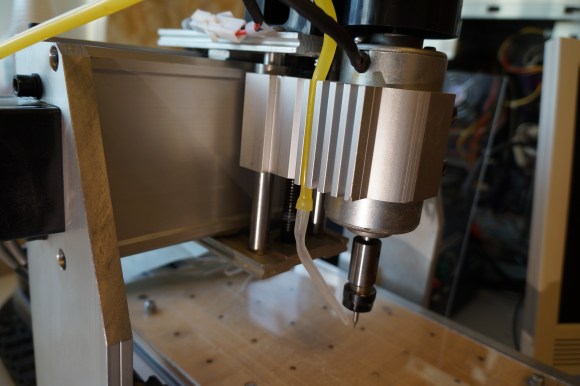

It appears the coolant flow is open loop, meaning the initial coolant reservoir is not replenished automatically. The coolant starts in a container and is moved via a pump through a silicone hose. At the end of the hose there is a nozzle mounted to the Z axis which points the coolant stream at the tool bit. The nozzle is plastic and made from a re-purposed and modified flux application container. [Peter] took advantage of the machine’s bed being made of slotted extruded aluminum. The bed catches the coolant which then travels down the channels to the front of the machine where it is collected in a custom made bin. The parts of this plexi bin were actually cut out using this machine! Gravity then drains the contents of this bin into another container residing at a lower altitude.

Believe it or not, the control boards for these relativity inexpensive CNC machines have a bunch of hidden features. One of them is a connection for spindle direction, it’s even silkscreened as such on the PCB. [Peter] tapped into these points on the control board and connected them to a custom made relay board of his own design. This board holds a SPST relay for the coolant pump and a DPDT relay for reversing the polarity on the spindle.

With the new board in place and wired up, both the spindle direction and coolant can be controlled via g-code commands courtesy of LinuxCNC. If you have a CNC3020 or CNC3040 router and would like to improve it’s capability, check out [Peter's] previous projects; Power Supply Upgrade, PWM Spindle Control and Limit Switches.

Filed under: cnc hacks