There are some types of projects that we see quite often here on Hackaday; 3D Printers, Development Boards and Video Game Hardware to name a few. Once in a while we see an optics-based project but those use pre-made lenses. [Peter] felt it was time to give home lens manufacturing a shot and sent in a tip about his experience.

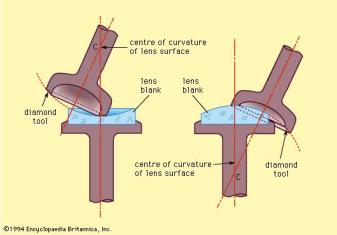

The typical lens manufacturing process starts off by taking a piece of glass and manipulating it into a rough lens shape, either by removing material or heating the glass and forming it in a mold. These lens blanks are then lapped using progressively finer grits of abrasives until the final lens shape and surface finish are achieved. The tool used to lap the lens is very specialized and specific to one lens contour shape. This lapping process can be very time consuming (and therefore expensive) depending on the quality and size of the lens being made.

Instead of using very specific tools to make his lens [Peter] wanted to use standard equipment so it was possible to make different lens sizes and shapes in the future. He did this by writing a parametric g-code file that can be used for any basic lens. The desired lens parameters are manually entered as variables in one location of the g-code file after which the machine control software, LinuxCNC, takes the g-code and drives a 3-axis CNC Machine to mill out a rough shape of a lens.

Three millimeter thick acrylic was used in place of glass for this experiment because it is easier to machine than glass. That is not to say there weren’t any problems during the milling process. [Peter] quickly learned that coolant was extremely important in the process. Without it, the acrylic would melt and fill up the flutes of the milling bit resulting in the bit pushing its way through the material rather than cutting through it.

The milling process did not leave a clear finish and required a lot of polishing. After becoming bored of polishing by hand [Peter] tried using a rotor tool… and then burnt a portion of the lens. Lesson learned!

The final lens is not anything special in comparison to commercial lenses but for a first DIY Lens attempt, it is amazing. If you are interested in making your own lenses the g-code file is available at the above link.

Filed under: misc hacks