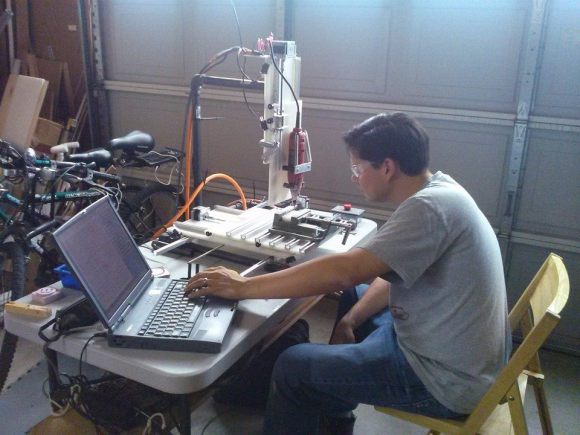

Cost is always a drawback and a hurdle when buying or building a CNC Machine, especially when building it just for fun or hobby. [Eric] was able to cobble together a working 3-axis rotary tool based machine for about $250, a few trips to the hardware store and a bunch of time.

The machine design is loosely based on this one he found on Instructables. [Eric] chose this style because he felt the boom supported tool would have been more stable and easier to build than a gantry style machine. Skate bearings, HDPE sliders and c-channel aluminum were used to support the XY table instead of traditional linear bearings and rails. All three axes are driven with stepper motors and 1/4″-20 threaded rods. The Harbor Freight dremel-style rotary tool helps keep the overall cost down.

[Eric] is going really old school by using TurboCNC as control software. TurboCNC runs on DOS and DOS-based OS’s (Windows 3.1/95/98). The software communicates to the stepper drivers via the parallel port. There has been a little difficulty getting files to this dedicated computer as it does not have WiFi or USB capability. May we suggest a slightly newer computer (with USB) and checking out LinuxCNC?

[Eric] is going really old school by using TurboCNC as control software. TurboCNC runs on DOS and DOS-based OS’s (Windows 3.1/95/98). The software communicates to the stepper drivers via the parallel port. There has been a little difficulty getting files to this dedicated computer as it does not have WiFi or USB capability. May we suggest a slightly newer computer (with USB) and checking out LinuxCNC?

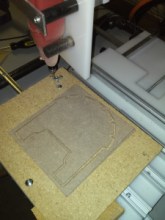

Although the machine has been successful cutting MDF and foam so far, solid plastic has been a challenge. The ultimate goal is to mill out circuit boards. [Eric] has tried cutting a few and now understands how difficult it is. He’s making continuous improvements and we’re looking forward to seeing the progress.

Filed under: cnc hacks